Introduction to Mini Diggers

What is a Mini Digger?

Mini diggers or mini-excavators are basically small and extremely multipurpose construction machines that are capable of handling digging, trenching, and demolition operations in narrow space or sensitive areas. Without any doubt, their compact size usually does not make you expect that they are able to give off a brilliant performance, at times even challenging their big brothers for small work.

In most cases, these machines have working weights that range from 1 to 6 tons and come with the following:

- A hydraulic boom and arm for precise digging

- Rubber or steel tracks for traction and stability

- A compact rotating cab or ROPS operator station

- Auxiliary hydraulic lines for attachment versatility

One should not be surprised to see the mini digger being a must-have machine for those jobs that care about the size of the place, the maneuverability of the machine, and the sensitivity of the ground—a machine that has made it possible for it to be the leading player in residential construction, landscaping, and the development of urban areas.

The Evolution of Compact Excavation

Mini digger has been changed a lot in the last 20 years. A machine that was considered a niche only for small backyard jobs has become a core part of every professional construction fleet nowadays. Today’s models are not only lighter and stronger but also smarter. They are equipped with:

- Zero tail swing for tight areas

- Advanced hydraulic control systems

- Telematics and GPS tracking

- Operator-friendly cabins with comfort features

In a lot of places all over the world, the sale of mini diggers has overtaken that of full-sized excavators. The reason for this is urban development, which is going up, and the need for less impactful machinery.

Why They’re a Staple in Modern Construction

So, why are mini diggers so popular?

Versatility – With the suitable attachment, mini diggers can handle any job from digging trenches to cutting concrete or leveling the soil. Transportability – They usually are light enough to be on a standard trailer, most of the time, a pickup truck can take them. Cost-effectiveness – They need less fuel, are cheaper to maintain, and have lower permit fees. Access – Are capable of entering places that are inaccessible for large machines, such as narrow streets, gates, or even small yards.

In case you are a general contractor, landscaper, plumber, or even a seriously ambitious DIYer, a mini digger would be a fantastic and time-saving tool that makes work more manageable and less tiring.

Types of Mini Diggers

Micro Diggers (Under 1 Ton)

Micro diggers refer to the smallest category of the mini excavator family, whose weight is less than 1 ton. They are perfect for jobs that require ultra-tight access and indoor demolition, as well as working in greenhouses or crawlspaces and passing through standard gates and doorways.

- Indoor demolition

- Working in greenhouses or crawlspaces

- Passing through standard doorways and gates

Considering their limited digging depth and lift capacity, micro diggers are still the best choice when it comes to delicate or confined tasks. They typically have:

- Extremely narrow tracks (less than 30 inches)

- Retractable undercarriages for both stability and access

- Simple joystick or lever control systems

Mini Diggers (1 to 3 Tons)

Mini diggers with the size of 1 to 3 tons are the most popular among other types. They manage to give the best of both worlds, i.e., size, and performance in a perfect balance. These machines are frequently encountered in:

- Residential construction

- Landscaping and trenching

- Utility installation

Typical features include:

- Digging depths of up to 10 feet

- Compact swing radius for close quarters

- Compatibility with a variety of buckets and hydraulic attachments

They are light enough for single-axle trailers but are still strong enough to handle small commercial jobs.

Midi Diggers (3 to 6 Tons)

Midi diggers are the most powerful mini excavator out of the three types. They are more productive and more reach. These machines can handle:

- Heavy landscaping

- Foundation excavation

- Commercial trenching and grading

The machines provide:

- Enhanced cab comfort

- Hydraulic quick couplers

- Advanced diagnostics and load control systems

Not only more complicated to tow and store than their smaller siblings, but midi diggers are also a fantastic alternative to full-size excavators for those who want more power in a compact package.

Key Specifications and Features

Operating Weight and Size

It is necessary to identify the weight class of a mini digger in order to be safe, transport it easily, and ensure compatibility at the job site.

Lighter machines are easier to move but offer less lift and dig force. Heavier models are more stable and capable but may require a larger trailer and tow vehicle.

Digging Depth and Reach

Mini diggers typically have:

- Dig depths: 5 to 12 feet

- Reach at ground level: 10 to 20 feet

- Dump height: 6 to 10 feet

With these specs, they are able to make utility trenches, excavate footings, and even load materials into small dump trailers or trucks.

Engine Power and Hydraulics

Mini digger horsepower is a:

- 10 HP (micro models)

- 15–25 HP (standard mini)

- 30+ HP (midi class)

What really counts, though, is the hydraulic system performance which decides how easily the machine can handle the likes of an auger or a breaker. Most of the hybrids feature:

- Standard and auxiliary hydraulic lines

- Variable flow rates for tool control

- Joystick-controlled swing, boom, and arm movement

Common Attachments for Mini Diggers

Buckets (Standard, Tilting, Trenching)

- Standard digging bucket: The most-used tool for digging and removal of soil

- Trenching bucket: Narrower width for utility trenches or footings digging

- Tilting bucket: Enhances the degree of freedom of the bucket allowing for slope grading or angled ditching

Fast switching between bucket types in seconds is made possible by quick coupler systems.

Augers, Breakers, and Thumbs

- Auger: Makes exact holes for posts, footings, or planting by drilling

- Hydraulic breaker: Destroys concrete, brick, or stone surfaces

- Thumb: Works together with the main bucket to grab logs, debris, and other uneven materials

Such tools turn your mini digger into a multi-role machine, thus making it an ideal choice for specialized projects.

Specialized Attachments

Other valuable tools of which the high value are:

- Rippers designed both for hard clay and frozen ground

- Compactors that can be used for trench backfill

- Grapples intended for handling brush or debris

- Plate tampers and mulchers

Without changing the machine, a mini digger with the proper attachment can do a hundred different jobs.

Top Uses of Mini Diggers in Construction

Trenching and Foundations

Mini diggers excel at one of their primary tasks which is trenching. Piping, electric line installation, or even just prepping drainage channels are some of the things that can be done with a mini digger as it is just the right one to do the job because of its precision and agility it is perfect for:

- Narrow trenches for irrigation systems

- Foundation footings for small structures

- Cable runs for telecom and utilities

In contrast, manual digging is a time-consuming and labor-intensive process, but a mini digger completes the job faster, cleaner, and with greater consistency. Most models are capable of trenching up to 6-10 feet which makes them versatile for typical residential or light commercial applications.

Mini diggers are also found in foundation work performing the following tasks:

- Excavate crawlspaces

- Dig slab footings

- Remove old concrete or rubble

- Backfill once the pour is complete

Besides that, they are perfect for the preparation of a tight site because of their ability to work close to existing structures and their minimal tail swing.

Landscaping and Site Prep

Landscaping professionals can’t do without mini diggers both for soft and hardscaping. Here is the list:

- Grading and leveling for lawns and patios

- Digging ponds or water features

- Stump removal and rock relocation

- Excavating garden beds and retaining wall trenches

One of the reasons why mini diggers are the very best landscape construction tools is their ability to install attachments like rakes, augers, and trenchers. Instead of multiple pieces of equipment, a single digger with quick attach accessories can:

- Remove turf

- Grade subsoil

- Dig post holes

- Transport materials across the site

Mini diggers also cause less ground disturbance, which helps to keep the lawns intact and prevents the formation of ruts—a factor that contributes significantly to customer satisfaction.

Demolition and Utility Work

In the realm of small-scale demolition, a mini digger with a hydraulic breaker or thumb grapple is hardly matched by any other type of machine. They are used by contractors to:

- Tear down old decks, sheds, or porches

- Break up driveways or patios

- Clear debris and vegetation

- Remove tree stumps or small foundations

On the utility side the small size of the mini digger gives the operator the possibility to dig close to existing structures without causing any damage that would lead to expensive repairs. They are perfect for:

- Water line repairs

- Gas main installs

- Electric cable trenching

- Sewer maintenance

Besides that they can work in small places without big crews or large machines, therefore they are the favorite tool of municipalities, utility companies, and plumbers.

Mini Digger vs. Full-Size Excavator

Job Site Access and Maneuverability

This is one aspect where mini diggers really beat out the competition. Firstly, a full-size excavator requires wide, open job sites and usually ruins the lawn, sidewalk, or driveway with its operations. On the other hand, a mini digger:

- Fits through gate openings as narrow as 36 inches (some micro models)

- Can operate safely in the close proximity of buildings or fences

- Works on sidewalks and in backyards

- Has a smaller tail swing and more limited turning circle

In case your workplace is cramped, urban, or residential, a mini digger will give you a far better access and maneuvering capability. Moreover, due to the 360-degree cab rotation, it also consumes less time on repositioning activities.

Cost and Maintenance

The difference is as clear as day between the two types of machines when it comes to price:

- Mini diggers have a price tag of $15,000–$65,000 if bought new

- Full-size excavators range from $100,000 to $300,000 and above

Besides fuel consumption, insurance, maintenance, and storage, all are cheaper for mini diggers. They are also more convenient to service as they have a lower downtime rate and in the majority of places, no special licenses or certifications are required to operate them.

Main benefits of mini diggers:

- Lower initial and operating costs

- Much easier transport (commercial trailers or trucks are not necessary)

- New operators can find the controls more user-friendly

Productivity in Tight Spaces

Full-size excavators are the best option for large jobs, however, mini diggers are quicker and more productive in small spaces. In many cases, full-size machines will have to reposition again and again, hit structures that are close by, or just not fit.

On the other hand, mini diggers:

- Complete jobs without damaging the environment

- Cut down set-up time significantly

- Provide access for detailed work and closer viewing (perfect for utility work or landscaping)

When the project is smaller or more fragile, the mini diggers will be more efficient in the area of one square foot of the job site.

How to Select the Appropriate Mini Digger for Your Work

Knowing Your Work Environment

Pick a mini digger after you have taken a thorough look at:

- Size of the job site

- Condition of soil and terrain

- Height of the place (trees, power lines, garage)

- Usage (daily, weekly, seasonal)

- Main activities (digging, trenching, grading, demolition)

By way of illustration:

- Confined, indoor, or landscaped areas = micro or sub-2 ton digger

- Outdoor landscaping and light excavation = 1.5-3 ton model

- Utility or commercial works = 3-6 ton midi digger

Furthermore, initiate the conversation about floor conditions. If the ground is on slope or is muddy, then the tracks might have to be wider and the blade can give support, as well as the offset boom to be able to reach further.

Matching Size with Job Specifications

If you properly match the weight class, it will be almost like you are allowing yourself to be neither too high nor too low in performance. A small home contractor will most probably not require a machine of 5 tons while a hardscape installer might find the 1-ton model too small and will require another one in just a few months.

What questions should you ask?

- Are you supposed to dig more than 7 feet down?

- Are you required to lift heavy things (rocks, metal)?

- Will you be using attachments like breakers or augers frequently?

Moreover, determine the necessity of a zero tail swing to provide additional safety in confined areas.

Dealer and Rental Considerations

In the event of the purchase or rental, just as much as the brand, the importance of your local dealer cannot be overlooked:

- Do they offer the service and parts?

- Can they offer assistance and guidance?

- Do they have the stock of the attachments?

- Is it possible to get financing or be eligible for the rental purchase?

Before making a final decision, try different models for a feeling of comfort, visibility, and the layout of controls which differ from brand to brand. If you are considering renting, then it is advisable to check if the company is providing the machines that are in good condition, from the recent year, and all the safety inspections are up to date.

Popular Mini Digger Brands and Models in 2025

Kubota, Bobcat, Takeuchi, JCB, CAT

These are some names of the leading companies in the mini digger industry with a brief description of what they are famous for:

- Kubota (U17, KX018, KX71): Dependable, lower priced, good dealer network

- Bobcat (E20, E26, E35): Newer styled cabs, improved controls, space-saving tails

- Takeuchi (TB210, TB225): The power to dig strong along with good hydraulic workability

- JCB (18Z, 19C-1E): Long-lasting and user-friendly layout are the features it is known for

- CAT (301.8, 302.7): High-end performance, operator comfort that can hardly be matched by others

All of them have models in different weight categories and with varied configurations such as canopy/open cab, enclosed cab with AC, and zero tail swing options.

Standout Features and Technologies

- Digital dashboards

- Load-sensing hydraulics

- Telematics for maintenance tracking

- Proportional joystick controls

- Auto idle and eco modes

One or two models even come with smart diagnostics, hydraulic quick couplers, and rear cameras—luxuries that once were only available to full-size machines.

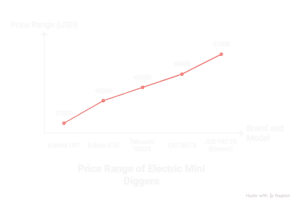

Price Comparison and Value for Money

Cost of Ownership

New vs. Used Mini Diggers

Purchasing new, the buyer can be assured of a warranty, the latest technology, and no history of wear and tear. Nevertheless, the base price of a new mini digger is around $25,000 and can go up to $60,000, depending on features and attachments.

On the contrary, used mini diggers could be a great option for the buyers who have budget constraints and are ready to sacrifice some features. A machine that is 2–5 years old with less than 2,000 hours can be

- Boom and arm pin tightness

- Cosmetic condition (especially rust or dents on cylinder guards)

Routine Maintenance and Repair

If looked after properly, mini diggers are low maintenance machines. Regular tasks include:

- Daily inspections (fluid levels, track tension, visual leaks)

- Oil changes every 250 to 500 hours

- Hydraulic fluid every 1,000 hours

- Track replacement every 1,500–2,000 hours (rubber tracks)

Annual service fees mostly cover $600 to $1,500, which varies with usage. Preventive maintenance is at the core of avoiding costly downtimes and thereby prolonging the life of your machine.

Fuel Consumption and Operating Costs

Mini diggers are classy in the use of fuel. A typical 1.5–2.5 ton model will consume:

- 0.5 to 1.5 gallons per hour of operation depending on the intensity of the work

Other costs to keep in mind are:

- Insurance (job site especially commercial)

- Maintenance of attachments

- Transport trailer upkeep

- Storage and security (only if at the job site)

Overall, the hourly cost of operation (fuel, wear, and depreciation) usually ranges from $8 to $20 per hour, which is very good for a machine that can do the work of several laborers.

Innovations in Mini Digger Technology

Electric Mini Diggers

Electric-powered mini diggers are gaining popularity. For instance, JCB 19C-1E and Volvo ECR25 Electric are some of the electric mini diggers that provide:

- Zero emissions

- Quiet operation (perfect for hospital, school, and night work)

- Less maintenance (no oil changes, no diesel filters)

They work for 4-6 hours on a single charge and can be recharged from a normal 240 V socket. The disadvantages are, however, that they are more expensive and have less power than the diesel ones.

Nevertheless, they are the right choice for:

- Indoor demolition

- Projects in cities with strict emission limits

- Companies that are committed to the environment

Telematics and Remote Monitoring

Modern mini diggers are installing telematics systems that bring:

- Real-time GPS tracking

- Alerts for maintenance and records of services

- Theft alerts with geofencing

- Performance data for better job planning

Such systems can be used on a smartphone, or a computer and are mostly useful for rental businesses and fleet managers.

Autonomous and Assistive Features

Some brands now offer:

- Auto-leveling booms

- Speed-sensitive hydraulics

- Integrated load calculators

- 360-degree cameras

These features make mini diggers easier for beginners and improve safety on busy job sites.

Environmental and Regulatory Considerations

Emission Standards

Mini diggers sold in the U.S., Europe, and Canada must comply with Tier 4 Final or Stage V diesel emission regulations. This means these machines generate lower levels of certain pollutants.

- Nitrogen oxides (NOx)

- Particulate matter (PM)

- Carbon monoxide (CO)

Electric models introduce new features that go beyond even these, as they provide clean, zero-emission alternatives, especially for urban and indoor areas.

Noise Pollution in Urban Sites

The noise level of mini diggers is lower than the one of full-size excavators. Most models average:

- 70–85 dB, which depends on load and RPM

Several local noise regulations set limits for construction noise. As a result, it becomes necessary to use electric or newer diesel models to meet these limits.

Eco-Friendly Practices

Contractors can do this by:

- Turning to bio-hydraulic oils

- Maintaining machines with a good service routine

- Not allowing fuel to leak or idling unnecessarily

- Buying the lowest power consumption for the selected attachment

These measures not only contribute to nature but also help saving fuel and cutting operating costs.

Conclusion

Mini diggers are the new phenomenon for the small, medium-sized construction, landscaping, and utility works. Their small compact size, versatility, and cost-effectiveness have made them the first choice for professionals who require reliability but are not interested in the heavy block of machines.

First, they are loaded with a full array of accessories; you have access to the newest technologies and are part of a company that focuses on producing low environmental impact machines. So, basically, mini digger is the machine that produces the most powerful performance of the full-sized one except that it is a much smaller, smarter operator-friendly one. It is therefore not surprising that they are experiencing such an upsurge in popularity in 2025 and beyond.