If your construction site needs force, accuracy, and deep penetration, a ripper attachment for a skid steer is a solution that hardly anyone can outmatch. It is one of those multi-functional and at the same time extremely simple devices which within a moment can change the compact loader into a loud and banging ground-breaker which can go deep through frost, roots, hardpan, or compacted gravel without even a bucket-tear-line showing.

In situations such as soil preparation for grading, digging heavy frozen soil, or taking back a rocky place, first of all, with the help of a ripper, you give your skid steer the advantage of the first strike. We are going to discover its functionality and mechanism, buying tips, and the reasons why Typhon, Blue Diamond, and Bradco brand are at the forefront one by one.

What Is a Skid Steer Ripper Attachment?

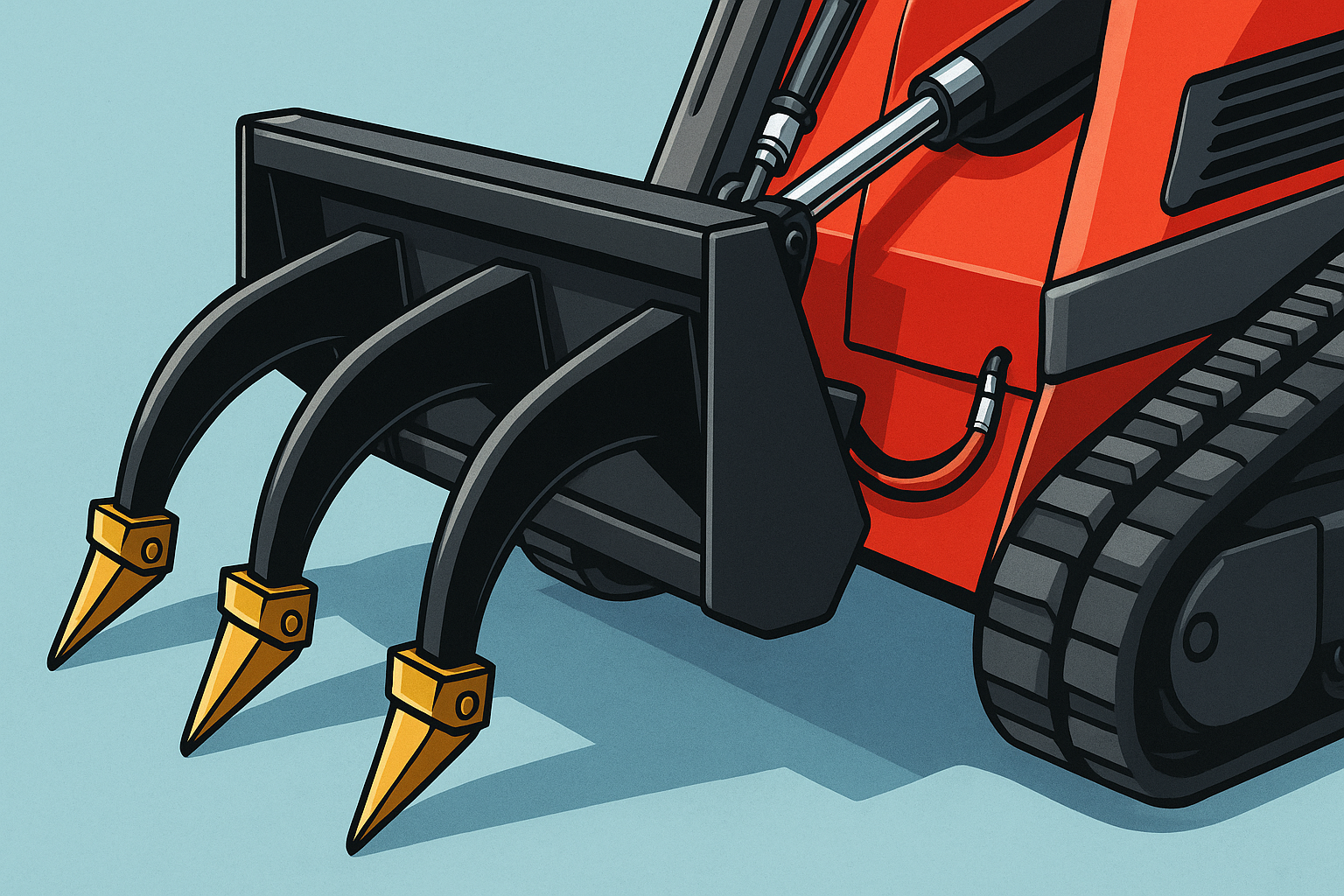

A ripper, which is also occasionally referred to as a scarifier, is an implement that installs on the quick-attach mechanism located on the front of the skid steer. It can have one to nine very sturdy shanks and these shanks are tipped with teeth that are both removable and dig straight down into the ground.

The steps of the operation might either be controlled by hydraulic or manual mechanisms that allow the raising or lowering of the tines, thus the hard material is broken so that the remainder of the work can be done by the bucket or blade.

Main usage examples:

- Breaking of frozen or severely compacted soil.

- Detaching of the asphalt or gravel layer prior to resurfacing.

- Removal of small stumps, roots, and old fence lines.

- Pre-ripping of clay prior to trenching or grading.

With this device, the attachment turns your agile skid steer into a quite powerful yet small bulldozer—perfect for the subgrade work that comes before demolition or the cleaning up afterward.

Design and Construction: Anatomy of a Ripper

Any quality ripper is based on three core components:

- Frame: The frame is generally made of ½-inch to ¾-inch steel plate for rigidity. The frames of Typhon carry steel, which is heat-treated to be resistant to twisting under impact loads.

- Shanks: These are the replaceable forged tines and most of the time are set with the adjustable spacing. If you want more depth then use straight shanks, but for better material roll take curved ones.

- Teeth: These are the hard parts of the tip—either bolt-on or pin-on—for a simple change after a long period of wear.

There are some optional upgrades like the hydraulic cylinder for the depth that you can control on the fly and quick-flip bar which enables you to reverse the rake for back-dragging.

Hydraulic vs. Manual Rippers

| Type | Operation | Advantages | Best For |

| Manual | Adjust tines by pin placement | Simple, inexpensive, low maintenance | Occasional or light work |

| Hydraulic | Controlled from the cab using aux hydraulics | Quick adjustments, precise depth control, greater efficiency | Contractors, roadwork, high-volume jobs |

A hydraulic ripper like the Typhon integrates directly with the skid steer’s auxiliary circuit, allowing real-time tine control—essential when cutting through alternating layers of soil and rock.

Performance Specs to Compare

While shopping, verify:

- Ripping Width: 60–84 inches are typical; correspond it with your machine width.

- Tine Count: 3–9 tines; less for deep ripping, more for surface scarifying.

- Tine Depth: 6–12 inches normally, can be 18 inches on heavy units.

- Required Flow: Most are operating on 15–25 GPM standard-flow systems.

- Weight: 400–1,000 lbs—this is especially crucial for equilibrium and the lifting power of the…

Without overspending on your skid steer and its hydraulic system, a perfectly matched ripper ought to facilitate your work and…

Other Top-Tier Options (2025 Market)

- Blue Diamond 84″ Hydraulic Ripper: Long-term use has verified its durability, can be manually or hydraulically tilted, 1,000 lb frame.

- Shank Ripper: Perfect as a general-purpose tool for soil preparation and reclamation, with replaceable CAT-style teeth.

- Ripper : Small size and low price make it ideal for landscaping and driveway renovation.

Any of these could be a good choice depending on the circumstance, but Typhon’s solution is the most harmonious combination of power and AI technology that can be utilized later.

Maintenance and Longevity Tips

- Put grease on pivot pins every 10 hours of work (if not sealed).

- Check shanks for bending—replace any with more than 5° of deflection.

- Tighten teeth; torque to manufacturer specifications.

- Clean the tools after every use to get rid of rust-causing dirt or salt.

- Keep your equipment inside—frozen hydraulic cylinders shorten the life of the seals.

If properly cared for, a ripper will be able to house 5,000–7,000 operating hours before it needs a major overhaul.

Safety Considerations

- Always make sure the tines are fully lowered before leaving the cab.

- Do not tear up the ground where there are buried utilities.

- Work at low speeds (2–3 mph).

- Employ hydraulic relief valves to avert over-pressure at the time of an impact.

Typhon’s ILMS-Lite™ (Intelligent Load Management System) keeps an eye on the pressure spikes and, in fact, immediately adjusts the flow, thereby ensuring that the machine remains steady even when the ripping is done in a vigorous manner.

How to Choose a Suitable Skid Steer Ripper

- Match the width of the ripper to the width of the machine’s wheelbase.

- Always check the hydraulic capacity and do not exceed the rated flow.

- Determine the number of tines according to the soil type (use less if you want more depth, and more if you want a finer finish).

- Make sure your quick attach is compatible.

- If you are a year-round operator, you may want to think about upgrading to hydraulic adjustment or depth sensors.

In case your work involves diverse soil conditions, a modular system such as Typhon’s 3-to-9 shank interchangeable setup can provide you with unparalleled versatility.

Ripper Attachment: A Necessity in Every Fleet

- Gives you the ability to work during the cold/frozen months.

- Helps to keep in good condition the parts which normally undergo heavy wear, such as buckets, blades, and tracks.

- Reduce excavation prep time by as much as 60%.

- With a minimal investment, you can maximize your machine’s earning potential.

Simply put, a ripper helps to change the function of your skid steer from that of a loader into one of a terrain-master which is able to handle the initial stage of any earthmoving campaign.

Skid Steer Attachment: The Frost Killer and Ground Dominator

The Typhon is by no means just another multi-purpose tool for the skid steer—it is the new standard for the convergence of the ground and the tool. When the operator is an individual who does not entertain the thought of slowing down even when the earth becomes frozen or the soil gets compacted, this is the attachment to be used. It brings together the brute mechanical power and the smart control technology of the next generation from Typhon.

If you are, for instance, cutting through a frozen tundra, tearing up an old asphalt, or pulverizing a compacted clay, the is the one to give you a guarantee of doing so.

Engineered to Shatter the Earth

The heart of the is its super strong steel frame, the very alloy family that is used in Typhon’s massive excavators. Every part of the tool is plasma-hardened and precision-laser cut to the micron, thus making it capable of even perfect alignment under the most extreme forces.

The 9-shank layout and the usage of the 3- and 5-tine modules, which are optional, allow for great versatility in the range of projects, types of work, that can be done:

- 3-Shank: Frost ripping deep (up to 18 inches).

- 5-Shank: Mid-depth soil loosening and subgrade prep.

- 9-Shank: Surface scarifying, root tearing, and wide-area reclamation.

The tungsten-carbide of teeth is what each shank holds; these are tips that can last up to four times longer than the standard ones used in rippers. The bend of the tine not only allows for deeper penetration but at the same time it also produces less drag—like claws cutting through stone.

Hydraulics – Precision at Every Inch

Traditional rippers use sheer, brute force; the is guided by a brain. Its hydraulic circuit balances the force equally throughout the two piston channels, thus discouraging one overstrain and keeping the engagement that is controlled at every tine.

The integrated sensors gather the data which is then given to the operator’s system of controls—thus allowing minute changes to be made regarding pressure and tine depth. The accuracy of the system is so great that it could be used to remove frost from asphalt without harming the base layer beneath.

Moreover, due to Typhon’s easily detachable hydraulic couplers, the may be attached to or detached from a working machine in less than 25 seconds, and additionally, there will be no loss of fluid or entry of air into the system.

Maintenance Made Effortless

- hydraulic filtration constantly removes very small debris from the fluid return lines.

- The grease-free joints cannot be greased from outside, thus daily greasing is eliminated.

- technology brings real-time maintenance alerts.

- You can replace the teeth without tools—simply twist, lock, and tear again.

What is the average maintenance time? Less than 5 minutes per week.

The Verdict: Infinite Possibility Meets Compact Power

Typhon is not just a tool—the power to command is being demonstrated here. In a surprising way, the technology of a full-size Typhon excavator is brought to the compact world by this intelligent unit which gives skid steers the ability to face the challenge of frozen ground, rocky soil, and even time.

For contractors, landscapers, and infrastructure crews who are the first to work in winter and last to leave the profit season, the is not a choice—it is a necessity. Your employment season is extended, your profit margin gets multiplied, and your machine becomes unstoppable force with this weapon.

When the ground becomes frozen next time, do not wait for the melt. Crack it by command. Do it with Typhon.

Conclusion

The story of a skid steer ripper attachment is told through the daily work it does from the very first shot at frozen clay until the last pass of grading. It is the fastest, most straight forward, and most effective way of achieving more power, more versatility, and more profit with the same machine.